Some Ideas on Inventory Management You Should Know

Wiki Article

The smart Trick of Inventory Management That Nobody is Talking About

Table of ContentsHow Inventory Management can Save You Time, Stress, and Money.Not known Details About Inventory Management Examine This Report on Inventory ManagementHow Inventory Management can Save You Time, Stress, and Money.

There are two primary approaches of tracking inventory: routine and perpetual. The primary difference between these is how usually information is upgraded. Regardless of exactly how commonly you track supply, you may intend to make use of one of the adhering to stock management methods: ABC Evaluation, ABC (Always Better Control) Analysis is stock administration that separates numerous products right into three categories based on pricing and is divided into teams A, B, or C.The items in the B classification are fairly cheaper contrasted to the A category. As well as the C category has the cheapest products of all three. EOQ Model, Economic Order Quantity is a method utilized for planning and also ordering an order quantity. It entails deciding regarding the amount of supply that need to be positioned in supply at any type of given time. Inventory Management.

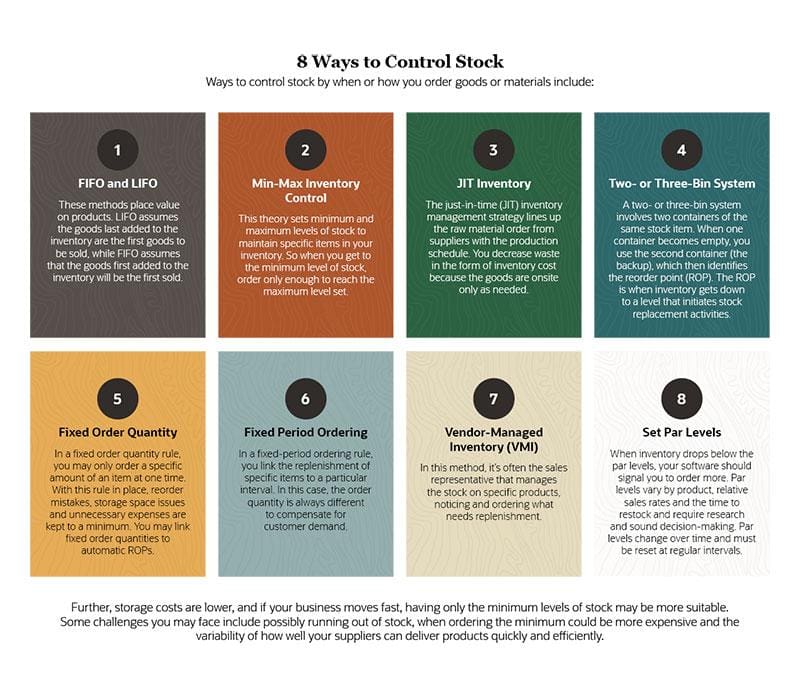

FSN Technique, This method of stock control describes the procedure of tracking all the items of stock that are not utilized often or are not called for regularly. They are after that categorized into 3 different classifications: fast-moving inventory, slow-moving stock, as well as non-moving supply. JIT Method, In the nick of time supply control is a process made use of by suppliers to control their supply degrees.

Some Of Inventory Management

VED Analysis, VED is a technique utilized by organizations to control their supply. It mainly refers to the monitoring of vital and preferable extra parts. The high degree of stock that is required for production generally warrants the reduced supply for those parts. Among the most critical aspects that a business must think about is the precision of the information provided in its supply databases.Wrike is a job management service that can help you do exactly that. With Wrike's product monitoring devices, important link you can manage all of your product group's activities in one area as well as obtain the most out of every task. Wrike's product launch automation helps increase product launches with a structured approach.

Stock administration tries to efficiently streamline supplies to prevent both gluts as well as scarcities. Four major supply monitoring methods consist of just-in-time management (JIT), products need preparation (MRP), economic order quantity (EOQ), and days sales of inventory (DSI). There are pros as well as cons to every of the methods, examined below. A business's supply is just one of its most beneficial assets.

A scarcity of inventory when as well as where it's required can be extremely destructive. At the very same time, Check This Out inventory can be believed of as a liability (if not in an audit sense).

Little services will certainly often maintain track of stock manually as well as establish the reorder factors and quantities making use of spreadsheet (Excel) solutions.

Some Known Facts About Inventory Management.

Suitable supply administration strategies vary depending upon the industry. An oil depot has the ability to store big quantities of inventory for prolonged periods of time, permitting it to wait for need to get. While storing oil is costly as well as riskya fire in the U.K. in 2005 led to numerous extra pounds in damages and also finesthere is no risk that the stock will ruin or go out of style.For companies with complicated supply chains i thought about this and also manufacturing processes, balancing the risks of supply excess and also scarcities is specifically challenging. To attain these balances, firms have actually developed a number of techniques for stock administration, consisting of just-in-time (JIT) and also materials requirement preparation (MRP). Some business, such as financial solutions firms, do not have physical stock and also so should rely upon service process administration.

Stock has to be physically counted or measured before it can be placed on a balance sheet. Firms normally keep sophisticated stock management systems efficient in tracking real-time stock levels. Supply is made up making use of one of 3 techniques: first-in-first-out (FIFO) setting you back; last-in-first-out (LIFO) costing; or weighted-average costing. An inventory account commonly contains 4 separate classifications: Raw materials represent various products a company purchases for its manufacturing procedure.

Operate in process (likewise known as goods-in-process) represents resources in the procedure of being changed into a completed item. Completed goods are finished products easily available to buy to a firm's clients. Product represents finished items a firm purchases from a provider for future resale. Depending on the kind of business or product being assessed, a company will make use of different stock administration techniques.

Report this wiki page